Nonead Industrial Collaborative Robot Flexible Palletizing System is the second generation workstation fully self-developed by Nonead, it’s automatic flexible robot palletizing workstation applied in the packaging lines in various industries. It is referred to as nPalletizer_CB2 for short, with modular designs, flexible and easy to operate, safe and reliable, with strong scalability.

If you prefer to configure the system yourself, you will receive a box that contains all the components of the whole system, which can be easily assembled and operated by referring to the instructions, and all electrical connectors are available to work as long as connected with plug in.

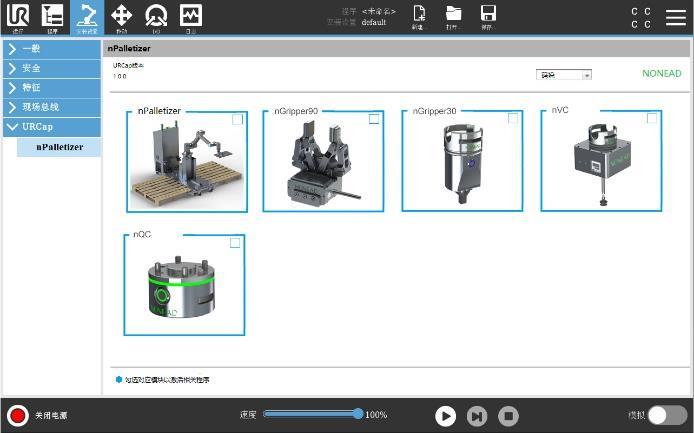

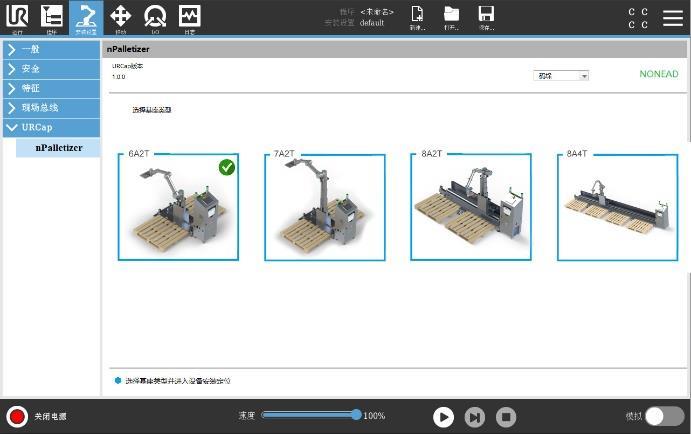

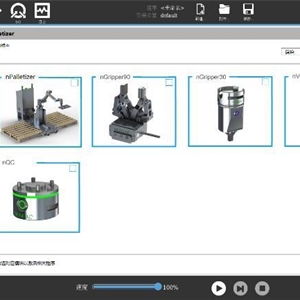

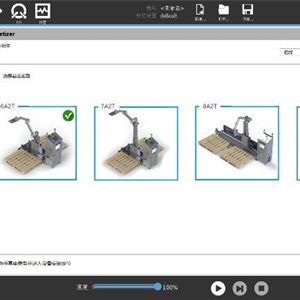

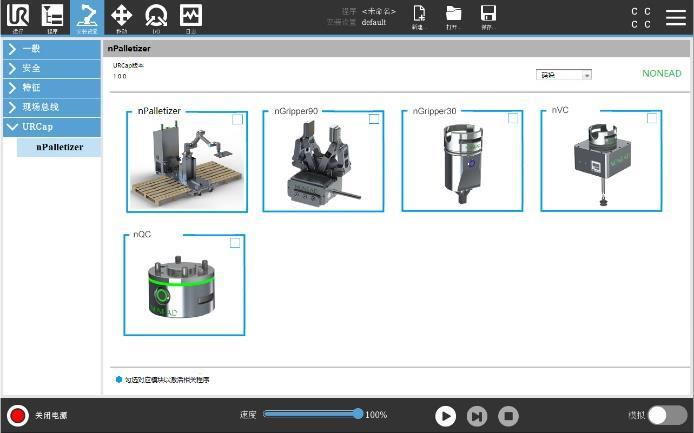

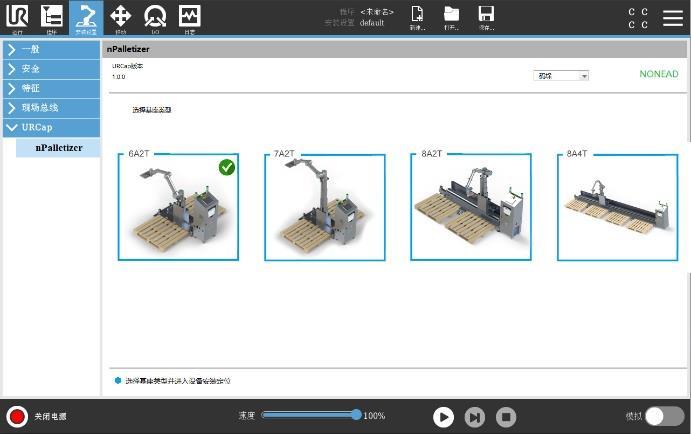

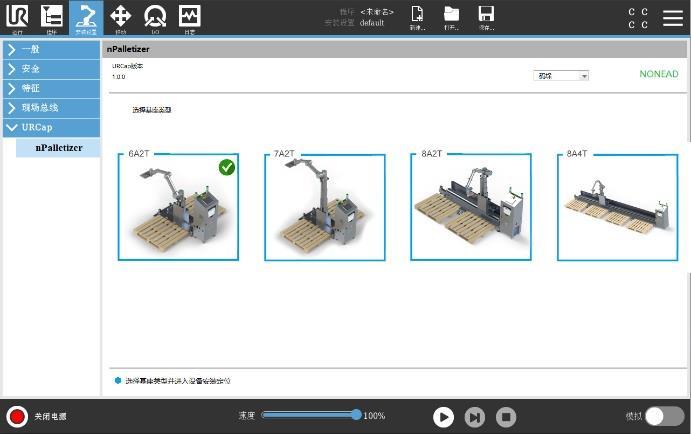

The nPalletizer_CB2 system consists of 4 series of products:

▸ Six-Axis Double -Pallet_CB2

▸Seven-Axis Double-Pallet_CB2

▸Eight-Axis Double-Pallet_CB2

▸Eight-Axis Four-pallet_CB2

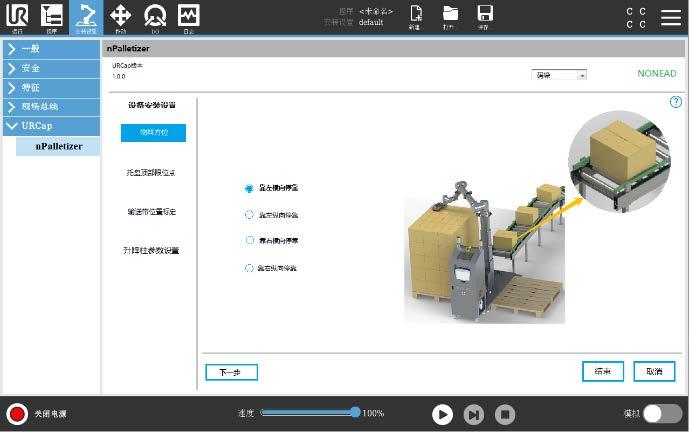

After the hardware are assembled, the product can be operated simply after 6-step initialization settings. The software system is based on the UR+ platform of Universal Robots, and Nonead Technology already integrated the application software into the Universal Robots system by URCap, therefore, operations of Nonead robots is just as easy as that of Universal Robots. Visual programming of different palletizing products simply requests to configure the box size, pallet size, palletizing type, number of layers, feeding position, etc.

Setup Steps of Initial installation:

1. Setting of incoming material orientation and direction 2. Location of incoming material position 3. Installation of incoming material detection sensor 4. Location of pallet position 5. Location of conveyor line position and height 6. Setting of the minimum and maximum height of the lift column

Programming Steps of Visual Program:

1. Setting of package size & weight 2. Setting of pallet size 3. Setting of palletizing type 4. Setting the layer height and styles 5. Edit the style for verification 6. Setting of pickup holding point, safety point, and transition point of abnormal returns

Palletizing Products Recommendation 1/3

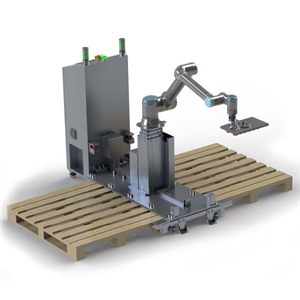

NH0246_Nonead Collaborative Robot Automatic Palletizing System, Six-Axis Double-Pallet_CB2

NH0245_Nonead Collaborative Robot Automatic Palletizing System, Seven-Axis Double-Pallet_CB2

Installation of parallel conveyor belt

Installation of Vertical conveyor belt

Choose a suitable installation method as per your environment. Additional location equipment is required for the conveyor belt, which always positions the fixed corner of the packaging box to the orange mark; add a blocking mechanism, and install the in-position sensor to this position. It is recommended to add a blocking mechanism before the grabbing position of the conveyor belt to ensure that there is only one packaging box at the grabbing position, and before the former packaging box is taken away, the latter one could not enter the grabbing position.

If there is a single product on the packaging line, the robot will load one pallet first and then another. The operator should take away the fully-loaded pallet in time and replace it with an empty pallet. If there are multiple products on the packaging line, the Nonead code reading module is recommended to be applied, with which the robot can place different products on different pallets separately.

Palletizing Products Recommendation 2/3

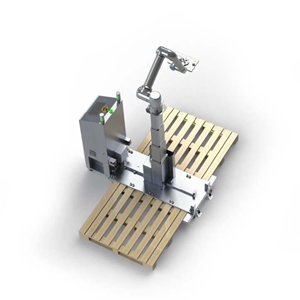

NH0247_Nonead Collaborative Robot Automatic Palletizing System, Eight-Axis Double-pallet_CB2

The coverage of the robotic arm is added to the Eight-axis Double-pallet robot, this series of products are suitable for those customers with higher palletizing requirements. For example, if it requires the packaging label to be towards the outside of the pallet, this system will increase the rotation of the packaging box during palletizing, with much higher flexibility and adaptability for customers with special palletizing requirements.

The maximum palletizing height of this series of robots will be higher than that of Seven-Axis and Six-Axis series.Either vertical or horizontal installation is available for choice according to the specific situation of the customer at site.

Palletizing Products Recommendation 3/3

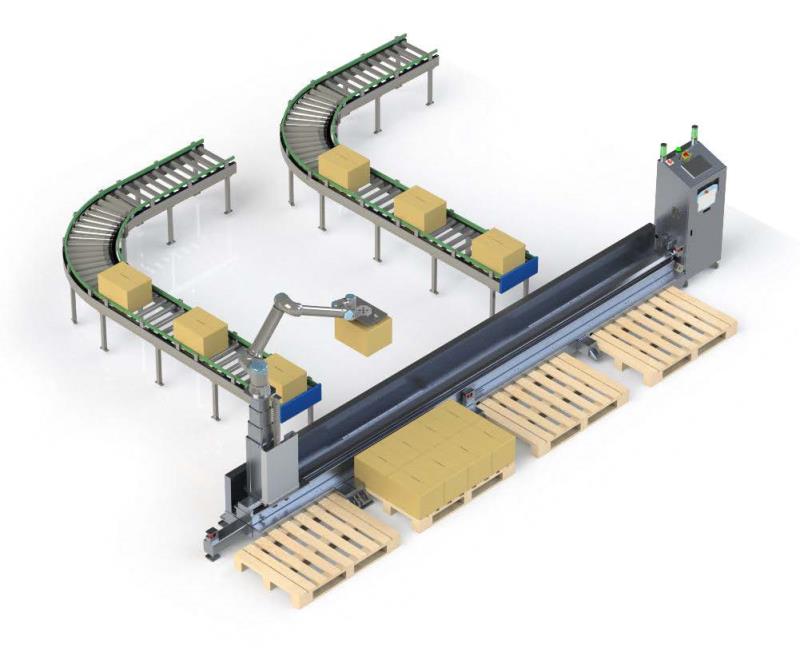

NH0248_Nonead Collaborative Robot Automatic Palletizing System, Eight-Axis Four-Pallet_CB2

The Eight-Axis Four-pallet series of robots are applicable for multiple packaging lines while with only one palletizing system operating. As long as the speed allows, the second-generation Nonead industrial collaborative robot flexible palletizing system can be installed with multiple sets of positioning and in-positioning devices to automatically pick up materials from multiple positions, which greatly saves the investment costs.

The Four-pallet series of robots are combined with Nonead code reading module, products on mixed packaging lines of can be placed separately on different pallets at the same time to solve the workload problem of manual sorting after the palletizing, and the products finished with palentizing can be directly delivered into warehouse.

System Highlights

▸Easy Assembly

The user can assemble all the components within 2 hours by referring to the installation manual. All electrical connectors are available to work as long as connected with plug in.

▸Mobile Operation

After assembly of the whole system, it can be manually pushed to the target position simply by one person with the Foot Master wheels at bottom, and then fold away the wheels to ensure that it cannot move, after which operating can get start. It can start operation again immediately after the reset of conveyor belt positions.

▸Simple Operation

No need any programming,just have some parameters set and demonstration-teaching, it can accomplish the palletizing or de-palletizing of the left & right pallets of a single packaging box. In case there are two disordered packaging boxes at the entrance line, which can be identified by the bar code, the palletizing function of one-pallet one-product can be realized simply by purchasing an additional code scanning module.

▸Small Space Required

nPalletizer_CB2 can be quickly applied to the existing packaging lines without re-planning.

▸High Performance

With extremely high performance cycle time and intelligent path algorithm, 20% higher efficiency than traditional palletizing or depalletizing systems. Multi-axis automatic linkage and high-efficient intelligent linkage algorithm achieves high performance.

▸Safe & Reliable

We only adopts the TUV security certified brand, Universal Robots, to ensure safety guarantee for the whole system, Meanwhile, third-party safety systems are also available to be adopted.

▸Free Software Upgrade

The URCap of this system will be iterativelyupgraded continuously, with newfunctions of palletizing and depalletizing adopted, and users can upgrade, if necessary, which is free of charge.

Strong Adaptability

nPalletizer_CB2 is with high scalability, with additional extended modules to realize corresponding functions, including 4 groups of extension modules:

1. NH0274 Second generation of Nonead Industrial Collaborative Robot Flexible Palletizing System with Code Reading Module_CB2

It’s available with separate palletizing of both left and right pallets with 2 disorder packaging boxes at the same time, both1D barcode and 2D QR code can be identified. It gets the size and weight of the packaging box by identifying the barcodes, and then carry out palletizing or depalletizint as per the operating requirements. The USB scanning device is inserted into the Universal Robot system without any equipment transfer, which greatly increases the stability.

2. NH0275 Second-generation of Nonead Industrial Collaborative Robot Flexible Palletizing System with Safety Module_CB2

The standard Nonead Collaborative Robot Automatic Palletizing System has been equipped with laser sensors on the left and right sides of the X moving axis to ensure personnel safety. When the robot in operation, it will stop working immediately in case the laser sensor is touched by mistake, yet it is not equipped with complete security sensor system to avoid any risk.

For users with high safety requirements, the NH0275 Nonead Collaborative Robot Automatic Palletizing System with Safety Module _CB2 is recommended. The Safety Module is available with two levels: Ordinary Safety and High Safety. The safety laser sensor adopted in the Ordinary Safety level is not security certified, but it protects more positions than the standard safety sensors. The safety laser sensor adopted in the High Safety level not only can protect more locations, but also the hardware is security certified.

3. NH0276 Second-generation Nonead Industrial Collaborative Robot Flexible Palletizing System with Bottom Traction Transport Module_CB2

When the total weight of the fully loaded pallet ≤500KG, our MiR250 system combined with Nonead bottom traction system can provide empty pallets for nPalletizer_CB2 without manual operation, and then transport the full pallet to the next task position in time. All tasks are operated automatically without manual involved.

4. Second-generation Nonead Industrial Collaborative Robot Flexible Palletizing System with Lifting Transport Module_CB2

When the total weight of the fully loaded pallet ≤1350KG, our MiR600 or MiR1350 system can provide empty pallets for nPalletizer_CB2 without manual operation, and then transport the full pallet to the next task position in time. All tasks are operated automatically without manual involved.

User Manual

/upload/202209/23/202209231746259553.pdf